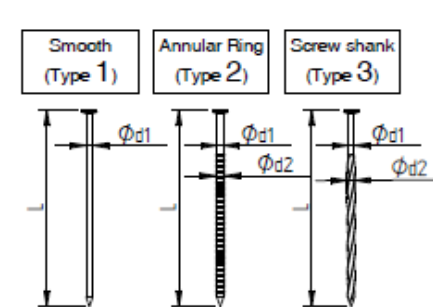

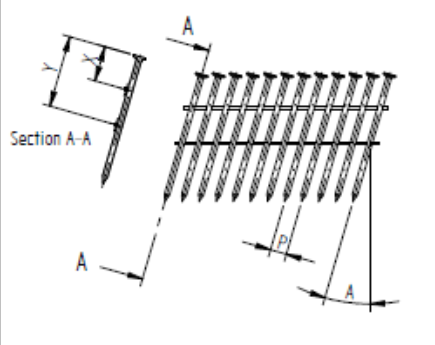

TECHNICAL QUALITY CONDITIONS Types and dimensions - according to figure 1 and table 1 and 2.

Table 1

| Dimensions., φxL, mm | pcs nails / Coil | kg / Coil | pcs / box | Coils / box | no. rows | kg / Coil | pallet with 5 rows of boxes, kg |

| 2.3×38 | 300 | 0.407 | 10800 | 36 | 6 | 14.67 | 660 |

| 2.3×40 | 300 | 0.427 | 10800 | 36 | 6 | 15.37 | 692 |

| 2.3×45 | 300 | 0.476 | 9000 | 30 | 5 | 14.28 | 642 |

| 2.3×50 | 300 | 0.525 | 9000 | 30 | 5 | 15.74 | 708 |

| 2.3×55 | 300 | 0.574 | 7200 | 24 | 4 | 13.77 | 620 |

| 2.3×60 | 300 | 0.623 | 7200 | 24 | 4 | 14.94 | 672 |

| 2.5×50 | 300 | 0.620 | 9000 | 30 | 5 | 18.59 | 837 |

| 2.5×55 | 300 | 0.677 | 7200 | 24 | 4 | 16.26 | 732 |

| 2.5×60 | 300 | 0.735 | 7200 | 24 | 4 | 17.65 | 794 |

| 2.5×65 | 300 | 0.794 | 7200 | 24 | 4 | 19.06 | 858 |

| 2.5×70 | 300 | 0.852 | 5400 | 18 | 3 | 15.33 | 690 |

| 2.8×60 | 250 | 0.767 | 6000 | 24 | 4 | 18.40 | 828 |

| 2.8×70 | 250 | 0.888 | 4500 | 18 | 3 | 15.98 | 719 |

| 2.8×75 | 250 | 0.948 | 4500 | 18 | 3 | 17.06 | 768 |

| 2.8×80 | 250 | 1.008 | 4500 | 18 | 3 | 18.15 | 817 |

| 2.8×90 | 250 | 1.129 | 4500 | 18 | 3 | 20.33 | 915 |

Tabel 2

| φd1, mm | φd2, mm | L, mm min. | L, mm max. | P mm | A mm | X mm | Y mm |

| 2.3±0,03 | 2.53±0,05 | 38 | 60 | 8±0,2 | 16°±1° | 8±0,75/19±0,75 | 24±0,75/37±0,75 |

| 2.5±0,03 | 2.75±0,05 | 38 | 70 | 8±0,2 | 16°±1° | 8±0,75/19±0,75 | 24±0,75/37±0,75 |

| 2.8±0,03 | 3.08±0,05 | 70 | 90 | 8±0,2 | 16°±1° | 19±0,75 | 51±0,75 |

Appearance

The nails should have a smooth top surface. Notches of the head are not allowed, the ones similar to those at the head of the notched screws. Under the head of the nails are allowed piles of material placed diametrically opposite. The nails must be straight, clean and free of oxides. Nails may have traces of mold on the stem under the head. A longitudinal groove or grooves with a depth not exceeding twice the limit deviation of the respective diameter shall be allowed on the rod. The tip of the nail must have a sharp angle of max.40 °.

Size deviations and shape deviations

– Minimum deviations in permissible length according to Table 2, Column 3 and 4.

– Boundary deviations in the diameter (side) of the nail rod according to Table 2, Column 1 and 2.

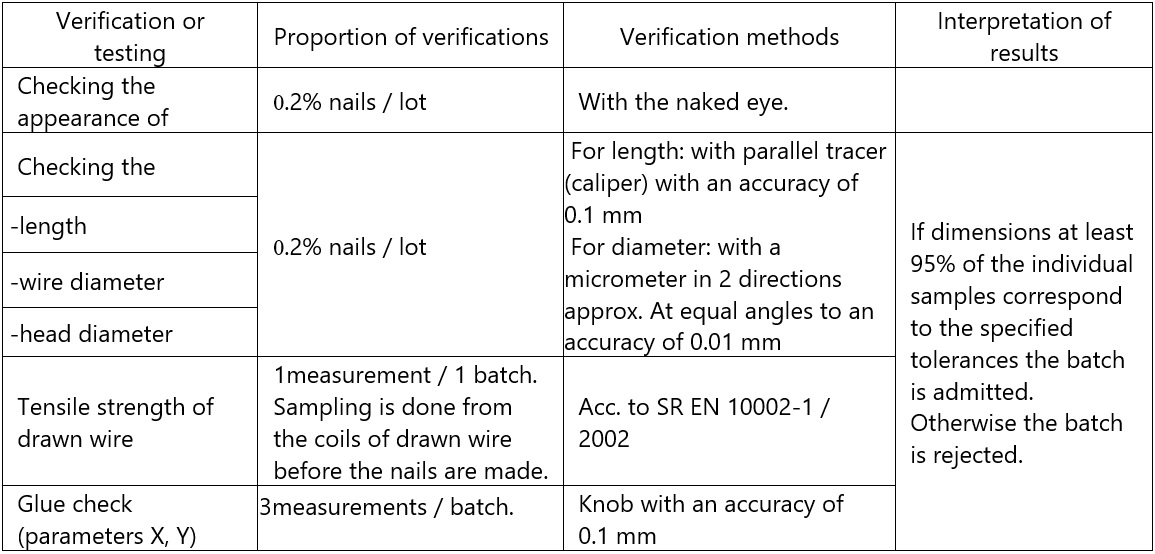

Rules for quality control.

The check is made on batches containing nails of the same type and dimensions.

The size of the batch is determined according to the dimensions of the nails, not exceeding the production of nails of the same type and the same dimensions in a day.

To check the quality of the nails, the following checks are made:

– checking the appearance,

-checking the dimensions,

-checking rectilinearity.

METHODS FOR QUALITY VERIFICATION

The verification and test methods are according to Table 3.

Table 3

Delivery, packaging, marking, documents

5.1 Welded nails on a 0.68 mm diameter coated wire are delivered Coiled. Each Coil has a number of 250 ÷ 300 welded nails (Table 1, Column 2) and is used for specialized nail guns.Coil nails are delivered in cardboard boxes with dimensions: 394x264x292 mm; 18-36 Coilers arranged in 3-6 rows (table 1, col.6) by means of 3 cardboard tubes with L = 295 mm and φext = 20 mm, separated by cardboard separators with dimensions 392 × 262 mm.

Cardboard boxes with a mass of 14-20 kg (table 1, column7), are arranged on a wooden pallet type EUR (1200 × 800 mm) on 3/5 rows (table 1, col.8 / 9), each row contains 9 boxes; total net weight per pallet approx.394-549 ± 5% kg (if the pallet contains 3 rows) respectively 656-915 ± 5% kg (if the pallet contains 5 rows). Each pallet with Coiler welded nail boxes is stiffened with cardboard corners, then wrapped in stretch foil. The pallets are tied in 3-4 places with 16 mm PP tape.

Boxes must be closed to ensure the integrity of the contents. Nails of the same size are inserted in each box.

Sticker labels with the following inscriptions are affixed to the nail boxes:

– trademark of the manufacturing company (on request);

– nailing the nails, according to this standard;

– dimension;

– no. nails / Coil, no. nails / box;

– no. Coils / box;

– lot no.

A paper label is applied on the pallet on which it is written: nail size, number of boxes and net mass.